Achieving Biocompatibility in DLP 3D-Printing

Prof. Dr. Thomas Griesser from Luxinergy unveiling the secret of the creation of biocompatible photopolymers and of the regulatory process to get these materials approved. Many interesting questions.

Professor Khoon Lim and his team at the University of Sydney have been hard at work developing materials that preserve the viability and bio-functionality of bio-printed tissues while realizing the speed, and scale of 3D bioprinting through the use of visible light.

It’s well-known that one of the biggest challenges in applying light-based 3D bioprinting techniques for tissue engineering and regenerative medicine is designing the right materials. The energy required to achieve polymerization can affect cellular viability and functionality, while conventional additive techniques are far too slow for practical application.

"The selection of light-source is also important as UV light-based crosslinking is detrimental to cell function."

Prof. Khoon Lim

As a photopolymer chemist, Lim focuses on developing light-activated material chemistries for DLP-based bio-fabrication and for the last 10 years has been experimenting with photo-sensitive cross-linkable materials.

“My work investigates applying the materials I’ve developed and how to modulate and design them to be adaptable to current light-based bioprinting modalities,” he said. “Primarily we’re trying to devise high-throughput tissue models that can be used in vitro to replace animal models for drug testing and other applications, now that the U.S. FDA (Food & Drug Administration) has approved this approach.”

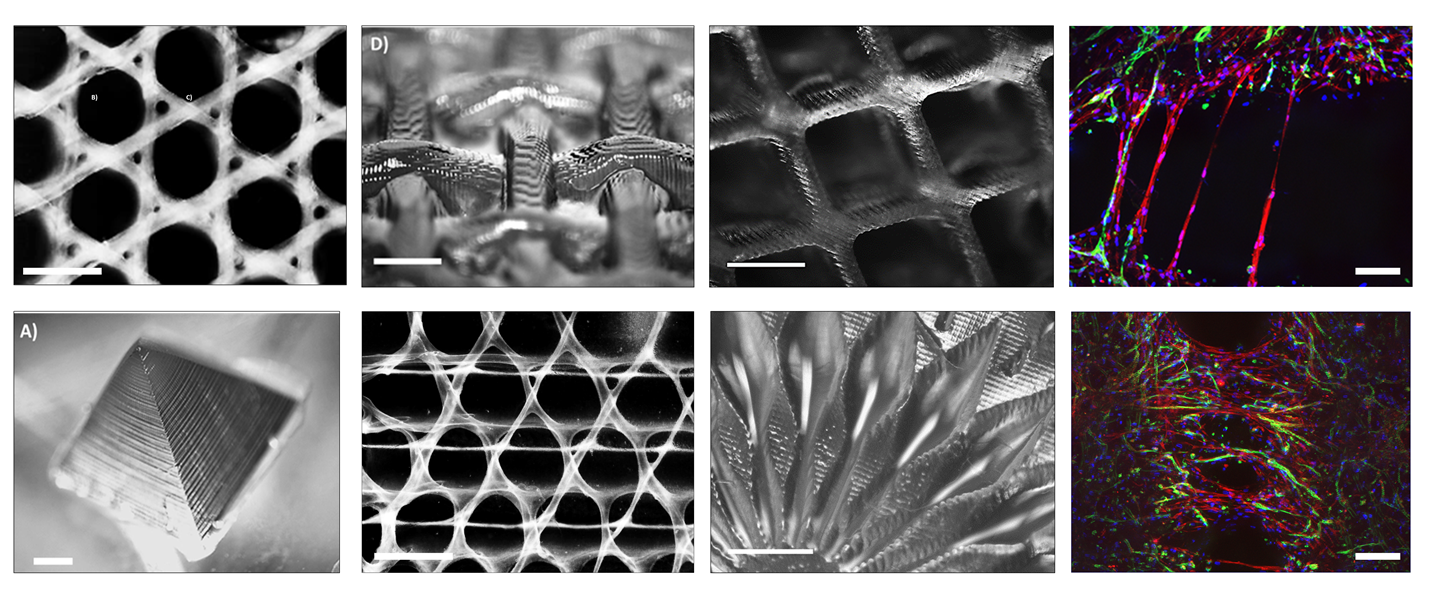

Light-based bioprinted scaffold (Credit by Khoon Lim)

The challenge with most light-based printing is that the material itself has to be cross-linkable in response to light as the stimulus. But this limits the library of materials available as most bioinks are not light-responsive. The selection of light-source is also important as UV light-based crosslinking is detrimental to cell function, and it’s imperative to maintain both cytocompatibility and bio-functionality so that the cells remain viable once placed in the body in order for the technique to achieve practical application.

The use of visible light can preserve these properties and through experimentation, Lim has developed specific bio-resin and hydrogel chemistries that respond to visible light, making 3D DLP bioprinting of tissues more practical in the surgical theater, dental applications, and more. This allows for a much broader range of light intensity, from 1 mW/cm2 all the way up to 100 mW/cm2, which is much safer for cells (controlling for heat, of course).

Oxygen inhibition is also a challenge that Lim has worked to overcome. From a polymer standpoint, it’s quite easy to crosslink in the absence of oxygen, but in living tissue, oxygen is ubiquitous. By varying multiple factors, including photoinitiators, their concentration, light intensity, and material chemistry in a systematic approach, Lim has been able to adapt his strategies to overcome oxygen inhibition and produce viable, functional tissue.

Finally, Lim and his team have also experimented with the impact of wavelength on bio-functionality. Most scientists have traditionally used 365nm wavelength, primarily because there is a popular photoinitiator that absorbs this well. But in a 3D hydrogel at that wavelength, cytocompatibility is preserved but functionality is not—the cells don’t remodel the matrix or make new tissue as well as they do at 450nm. So, Lim and his team have adapted their materials to tolerate various wavelengths, including 405nm, to optimize tissue build.

“We are making material to work with the DLP bioprinter, but why not also evolve the printer?”

Prof. Dr. Thomas Griesser from Luxinergy unveiling the secret of the creation of biocompatible photopolymers and of the regulatory process to get these materials approved. Many interesting questions.

With multiple modalities available for bioprinting, Lim recognizes that each comes with pros and cons and researchers have to be willing to experiment with every variable in the process.

“We are trying to improve both the technology along with the material,” he said. “We are making material to work with the DLP bioprinter, but why not also evolve the printer?”

Lim’s work has proven that contrary to popular assumption, light is a viable source for bioprinting to preserve cell viability and function. “There are so many printers, techniques, and more that you can capitalize on, and lots of room for experimentation,” Lim said. “In the grand scheme, from a clinical standpoint, the outcomes are what’s most important.”

"In order to have something that’s useful, it also has to be practical. I’m partial to light but open to other ideas.”

To that end, Lim has experimented with a wide range of equipment from high-end printers to hardware-store lightbulbs. While resolution matters, he says it’s also important to have something that’s accessible in order to achieve clinical applicability.

“We’re already seeing DLP bioprinting moving into clinical settings, in hospitals, in dentistry…people are very open to it and the buy-in has been very quick. That’s unusual in the medical field, which is typically slower to adopt new technologies,” Lim said. “But in order to have something that’s useful, it also has to be practical. I’m partial to light but open to other ideas.”

Lim says he’s particularly excited about the potential for volumetric 3D printing techniques to deliver much faster speed and scale for light-based bioprinting applications. “Some colleagues are working on crosslinking within three to five seconds, producing a bulk volumetric structure,” he said. “That’s not possible with standard lithography-printers, but I’m really excited about the possibility, given the speed of those results.”

In a field test we evaluated a UV Projector with the consumer video chip DLP 660TE and the industrial version DLP 670S from Texas Instruments in a setting as it is used in In-Vision's Light Engines.

Lim’s approach to using visible light opens up a new world of possibilities for in situ polymerization. Using light to encapsulate cells—essentially achieving targeted crosslinking by applying light in a specific area—allows for directed cell behavior. For example, a surgeon could place material inside the body, then apply the light to achieve transdermal polymerization.

While there’s a lot of hype and excitement around 3D bioprinted organs, and Lim says he’s excited about that possibility, right now the goal is making measurable progress in conquering incremental applications that build confidence in the technology, demonstrate feasibility and provable outcomes.