How to use Phoenix, the first industrial 4K UV Light Projector, as an 8K Light Engine

In-Visions proprietary pixel shift technology makes it possible to quadruple the number of accessible pixels of the Phoenix Light Engine to gain higher resolution.

Exploiting the integrated 4-way-actuator leads to superior surface qualities

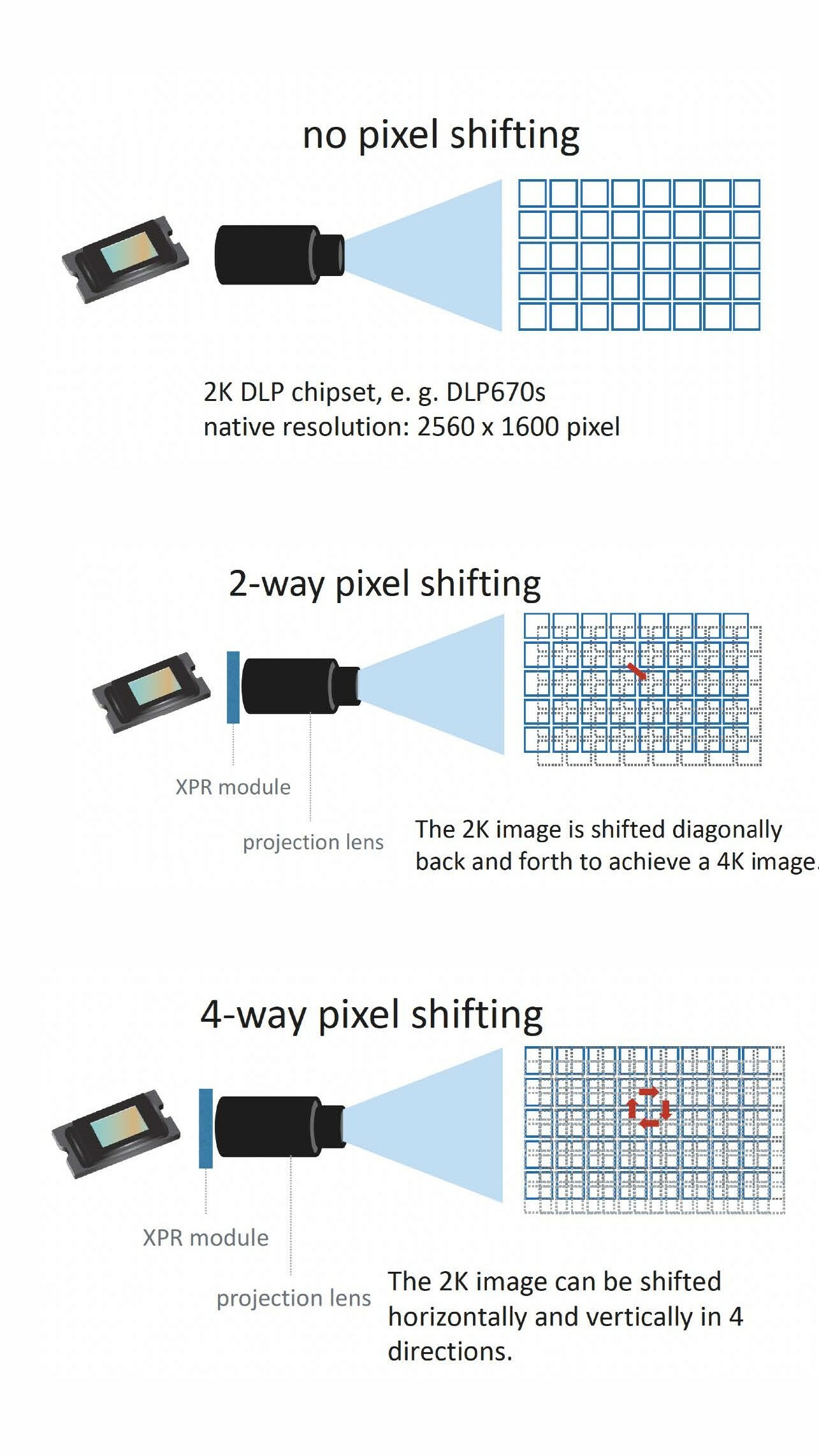

What is better than resolution to achieve highly complex 3D-printed parts with outstanding surface qualities? Right, it´s higher resolution. Although DLP-Technology offers various possibilities, there is a limitation in the number of native pixels on a single chip. Currently, this limit lies at 2K resolution or about 4 million pixels per image. And there will be no native 4k-Chip in the sooner future. Higher resolution in the image plane usually shrinks the image size simultaneously. A feasible way to get out of this dilemma is to shift pixels between each exposure and to control the print at the sub-pixel level. With this method, a higher resolution can be achieved without losing the size of the image.

4-Way-Shift

The pixel shifting method was first used in display applications and has also found its way into 3Dprinting, where it is used to achieve higher resolutions and a better surface finish.

Most 4K projectors on the market are based on a 2K DMD chipset and implement a 2-way pixel shifting to achieve a 4K image. In-Vision’s DLP670 Phoenix light engine implements not only 2-way pixel shifting but also 4-way pixel shifting, where the pixels

can be shifted horizontally and vertically as well. This leads to an 8K image.

An example

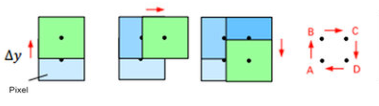

To improve the resolution of our image, we will use 4-way pixel shifting.

The pixels get shifted horizontally and vertically in four directions to improve the resolution; the image below shows the sequence of the shifting.

Let’s assume that our material needs to be exposed 16 seconds with an intensity of 8mW/cm² for optimal curing. Using 4-way pixel shifting, we will split the single exposure into four exposures for each layer. One possible way would be that the first exposure for 4s is used to create the base structure. The following three exposures, each are used to create the subpixel features to fit the designed part better.

What's important?

When working with this sophisticated method, calibration of the shifter movement is the key to gaining the best results. In-Vision ensures with its technology the optimised signal form to reduce the switching time of the micromirrors. The DLP UV projector Phoenix has been available with a serial pixel shifter since its launch in April 2021 and has undergone many improvements and optimisations.