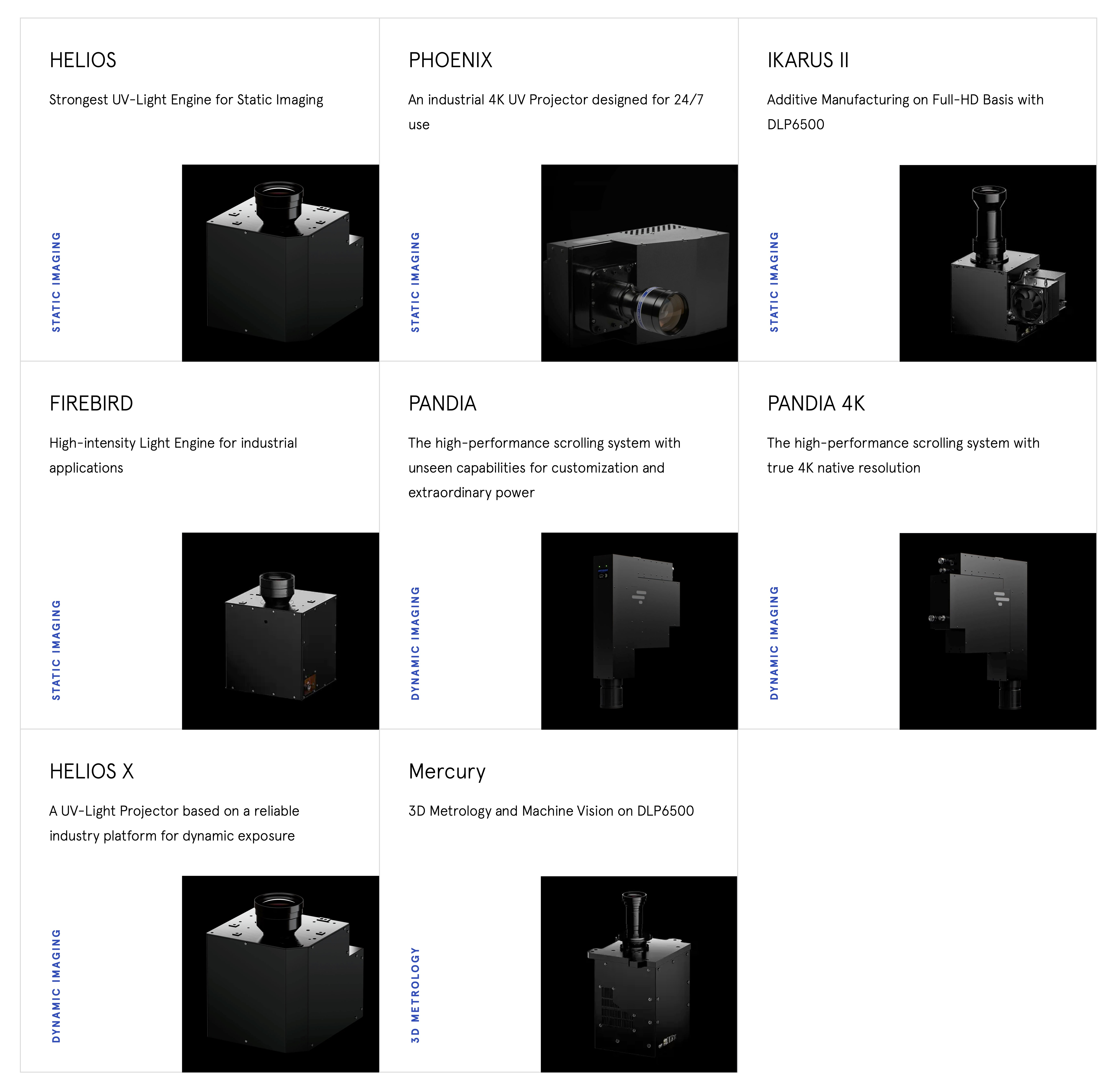

PANDIA 4K - The high-performance scrolling system with true 4K native resolution

| Chipset | DLP991U |

| Micromirror array size | 4096 x 2176 |

| Wavelengths (LED) | 365, 385, 405 and 460nm |

| Number of simultaneous wavelenghts | up to 3 |

| Image Resolution | 4K |

| Image Size | 29.263mm x 15.545mm (7.1um Lens) |

| Standard lenses | 2µm, 7.1µm, 35.7µm (others on request) |

| Optical output power (image plane) | up to 9 W/Wavelength |

| Contrast | Min. 1:300 (ANSI) |

| Uniformity | >90% (without software correction) |

| Cooling system | Watercooled |

| Interfaces | Gigabit Ethernet, Optical PCIe |

| Software options (excerpt) | Scrolling algorithms; DMD rotation compensation, grayscaling |

Some of the main features of PANDIA 4K:

- Scrolling availability for larger building areas: PANDIA is designed for moving exposure while calculations are done onboard.

- Stackability for more productivity: The small width of the system allows projectors to be lined up down to very small pixel sizes to build systems with large building areas.

- An open system with unlimited options for customizing: The built-in FPGA allows users to customize their applications or use prepared Software. The onboard FPGA opens up to 7 Gigabytes for image storage, programming logic, and DSP slices for customization.

- Multiple wavelengths for working with multi-materials: two independent illumination modules provide up to three different wavelengths.

- Variability: Pandia comes with a telecentric lens with a pixel size of 7.1um; any other resolutions can be easily realized with custom lens developments in-house at IN-VISION.

- Watercooled system for highest optical power: The optimized water cooling provides full power for all applications – up to 9 watts per wavelength.

- High-Speed Data Interface: Maximum transfer rates are realized using Gigabit Ethernet or an optical data interface, which is flexible, lossless over long distances, and immune to electromagnetic interference.

- Field changeability of the illumination modules: The customer can easily swap out the two LED modules, which does not require further calibration or set-up. This can be done after thousands of hours of uptime without degradation.

- Onboard User-Interface for operators: An onboard HMI informs the operator about the operating status and critical parameters.