HELIOS X - Strongest UV Light Engine for high-speed scrolling

The most powerful UV-Light Engine for Additive Manufacturing

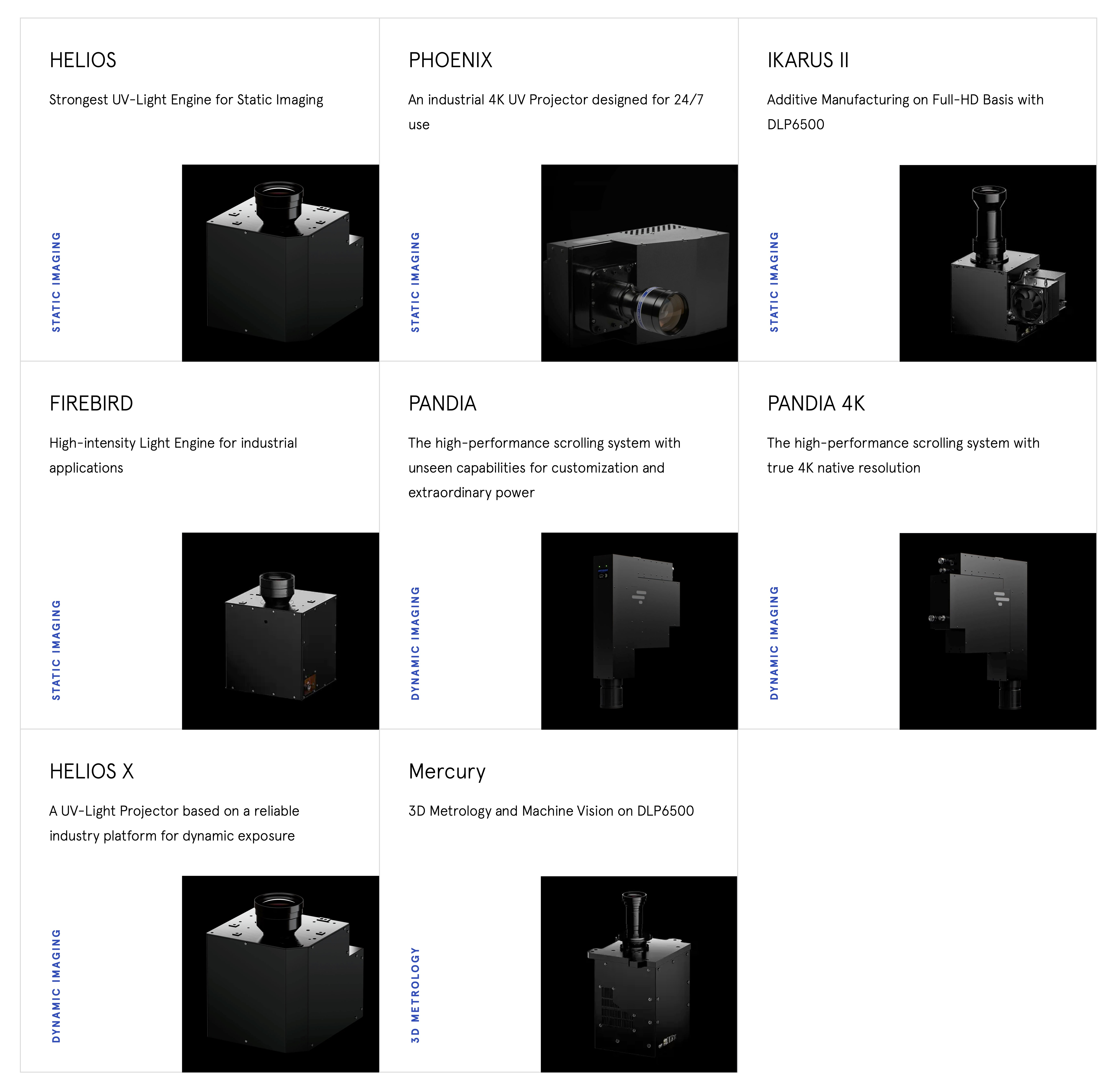

A brand-new UV Light Projector based on a reliable industry platform for dynamic exposure. HELIOS X combines the proven optical system with new electronics. To name some of the new features: it includes an open FPGA on board making the unit as open and customizable as possible, plus HELIOS X gives you the possibility to use an optical PCIe-Interface to ensure high-speed scrolling.

| Chipset | DLP9000X |

| Micromirror array size | 2560 x 1600 |

| Wavelengths (LED) | 365, 385 and 405nm |

| Standard lenses (others on request) | 6 | 30 | 75 | 150 | 162µ |

| Optical output power (Image plane) | up to 16W (wavelength-dependent) |

| Contrast ratio | up to 1:300 ANSI |

| Uniformity | up to 95% acc. to IEC61947 (Lens dependent) |

Podcast with CTO Christof Hieger

CTO from In-Vision Christof Hieger explains in a podcast from Ingenieur.de what has led the company to develop the Helios Light Engine.