Additive Manufacturing based on Stereolithography

October 2024

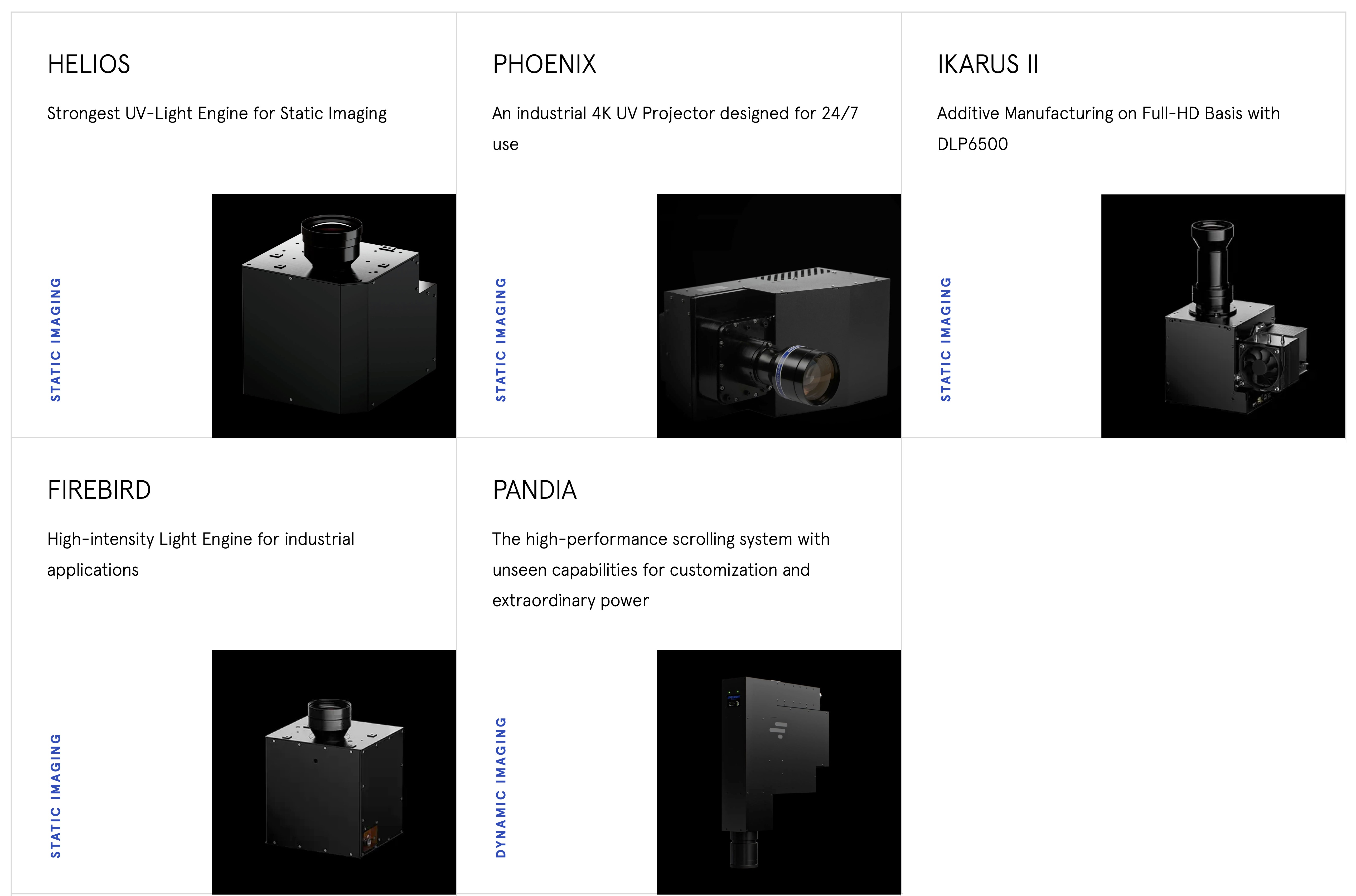

Additive manufacturing, or "3D printing", has been around since the early 80s of the last century. Since then, the technology has been mainly used to manufacture prototype products or showcase models. A lot has changed since these early days of rapid prototyping. Now, Digital Light Processing (DLP®) lays basis for a new era of additive manufacturing: in DLP based resin printers a liquid photopolymer is selectively cured by structured light through vat photopolymerization. For this method of stereolithography high precision UV projector from In-Vision are used.

In partnering with Texas Instruments and our customers, who are spread out over four continents, we have been able to advance this technology to an extent where mass manufacturing has become reality. The products printed by help of our optical engine projectors span from spare parts in industrial applications over pre-forms for jewelry production, every-day household articles to tissue printing in medical applications. This technology is a game-changer for how we think of supply chain today. It literally takes seconds from initial design to a tangible product in your hands.